The company RUPET formy a modely s.r.o. is engaged in design engineering and manufacture of molds for automotive, rubber and chemical industry.

The design and manufacture itself takes place in company RUPET formy a modely s.r.o., which is part of RUPET International s.r.o and it is a successor of well known company TOS Čelákovice which has a many years of practice in this industry.

The company RUPET International s.r.o. is registered in the Commercial Register kept by the Municipal Court in Prague, Section C, Insert 25487.

IN: 47541849

TIN: CZ47541849

The company RUPET formy a modely s.r.o. is registered in the Commercial Register kept by the Municipal Court in Prague, Section C, Insert 63910.

IN: 25717693

TIN: CZ15717693

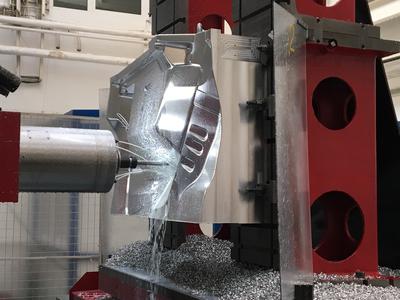

The main manufacture program is an aluminium and steel molds which are usually used in automotive industry as a prototype and sries tools, single purpose tools, control gauges and jigs. We cooperate with our customers from beginning thus means from the development of part production technology to the production of tools because we want to satisfied our customers. Thanks to prototype tools is possible to test various technologies and thus optimize parameters of serial tool.

Our design engineering department consults with the customer its requirements with regard to the functionality of the tool, the requirements and habits of the customer. Thanks to modern computer stations and direct contact with the customer we are able to make changes very quickly during the manufacture.

We use the secure data transfer system ODETTE OFTP2 and our own FTP server for the transfer of large data volumes. We use the Catia V5 for design, and we use Autodesk Inventor HSM for CNC programming. The maximum tools dimensions which we are able to produce is 2 200x2 500 mm and maximal weight 5 000 kg for one part. We use CNC and classic technology machining for the production of individual parts.

The whole production process takes place in our company and thus we are able to react very quickly to a change in a tool or jigs.

We offer our customers a complete service, which usually begins in the design department of 3D structures, then goes through the creation of milling programs, to milling shaped parts. We machine other parts on conventional machines. The final assembly and measurement is performed at assembly workplaces.

Our company uses air-conditioned halls with an area of approximately 2000 m2 with cranes up to 6,3 t. our machinery:

Working stations

4x design workplace with Catia V5 program

2x workplace for creating milling programs with the Autodesk Inventor HSM program

2x workplace for creating milling programs with the Surfcam program (3 axis and 4 axis)

CNC milling centers

1x horizontal boring mill FERMAT WFC 10 CNC HS (4 osy)

1x horizontal boring mill FERMAT WFC 10 CNC (4 osy)

1x vertical milling center HAAS VF8/40 (3 osy)

1x vertical milling center HAAS VM6 (3 osy)

1x horizontal milling center TOS FHK80A

1x vertical milling center Klopp

Conventional machines

2x large cutter

3x small cutter

1x lathe

2x horizontal boring machine

2x column drill

2x stand drill

Welding aluminum / steel / stainless steel

1x welding set Fronius MagicWave 5000

1x welding set Fronius VarioSynergic 5000

Control workplace

Measuring arm ROMER Absolute Arm 7320